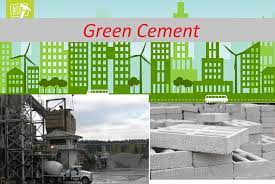

The process of making green cement is becoming more popular. These types of cement are known to have several positive environmental benefits and are a good option for sustainable building. Several ecological benefits are also associated with greener construction. Aside from being environmentally friendly, this concrete can also reduce greenhouse gas emissions. In addition to being eco-friendly, they may also conserve energy. They are produced from recycled materials and use less energy than conventional cement.

The production of green cement is an environmentally friendly process.

It requires less heat and releases 80% less carbon dioxide. Making green concrete is also more environmentally friendly because it requires less energy to create. The use of sustainable materials is becoming more critical, as it is increasingly challenging to develop new buildings and roads. This means that a shift to more eco-friendly cement is necessary. But how does green cement differ from regular cement?

Green cement is also more efficient than conventional cement.

In addition to being more durable and robust, green cement emits less carbon than traditional concretes. Additionally, it requires far less energy to produce. Its advantages include low chloride permeability, corrosion resistance, and early strength. It can also withstand cold temperatures and freezing conditions. In addition, it can last twice as long as conventional concretes. Finally, its pre-heating feature enables manufacturers to reduce the energy consumption of the manufacturing process.

The manufacturing process of traditional Portland cement produces a significant amount of carbon dioxide and heat. Limestone and clay materials are heated to over 1200 degrees to make the clinker during this process. As a result, in each tonne of cement produced, approximately 0.6 to 1.1 tonnes of carbon dioxide are released into the atmosphere. Because of these air pollution concerns, the manufacturing process for green cement has been designed to minimize harmful emissions. But this does not mean that green cement is not a desirable option for all projects.

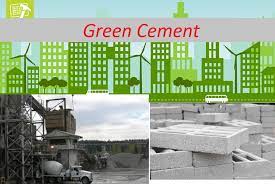

However, the green cement produced by making cement is not entirely eco-friendly. The term is not a precise definition. It depends on the definition of “green” and its use. In some cases, green cement is defined as one that uses less than a quarter of the energy used in the cement industry. In addition, it must be made with fly ash. The other types of cement are made of a different kind of carbon material that is more suitable for concrete.

In the US, the cement industry is one of the most energy-efficient industries globally. The demand for green cement has also grown due to energy efficiency and environmental concerns. The latest guidelines on environmentally friendly construction have increased the demand for greener cement in recent years. It is better for the environment and reduces the carbon footprint of a project. The carbon emissions from construction have become an essential factor in the US economy, making greener cement a good choice for environmentally conscious homes.

The green cement market has increased in the past few years.

As a result, there are many green cement varieties in the market. These include magnesium oxychloride cement, calcium sulfoaluminate cement, and ferrocrete. Consequently, these products are considered to be more sustainable than conventional cement.

Green cement is not an innovation. It is a suitable material used in the construction of buildings. The cement industry has been addressing the impacts of carbon dioxide on the environment for decades. Whether or not it positively affects climate change is another matter, but green cement has been around for thousands of years. As the cost of energy-intensive processes of making cement increases, so does the cost of energy-efficient products. As a result, greener alternatives are becoming more widely used.

There are many other advantages of using eco-friendly concrete.

The product does not compact or settle, creating massive space for building and transporting goods. These factors can lead to significant cost savings. Geotechnical engineers are discovering that eco-friendly concrete can also save money. In addition to being more environmentally friendly, this type of cement has many benefits that aren’t apparent to the naked eye. Aside from being highly reliable, this type of concrete is a good choice for construction, as it helps protect the environment.

As Canada’s biggest provider of maintainable structure materials – and with concrete a fundamental part of a large number of those items – Lafarge Canada is remarkably situated to affect the way we assemble the urban communities we want. We offer mixed concretes and valuable cementitious materials as arrangements, and presently, with our demonstrated estimation framework, you know precisely what influences your decisions to have on our current circumstances.

Execution and maintainability go inseparably.

We can give decreased CO2 concrete choices to meet all of your presentation prerequisites. Our quality control groups and designers have committed, and rigorous testing offices affirm all performative parts of the mix best for your undertaking. So, click beneath to dive deeper into projects that have effectively diminished their CO2 sway without surrendering quality or execution – then, at that point, reach us so that we can track down the correct answer for you.

Notwithstanding the natural objectives, there are various ecological expectations. The most significant are:

To stay away from the utilization of materials that contain substances on the Environmental Protection Agency’s rundown of unwanted materials, not to decrease the reusing capacity of green cement contrasted with regular concrete and not with increment the substance of risky substances in the wastewater from substantial creation contrasted and wastewater from the design of existing noteworthy sorts.

Different substantial sorts are tried for usefulness, changes in functionality after 30 min., air-content, compressive strength improvement, E-modulus, heat advancement, homogeneity, water division, setting time, thickness and permeability. Moreover, ice testing, chloride entrance and an air void examination are done for the cement in the forceful natural class.

The water/substantial proportion, water/folio proportion and the chloride content are determined from the blending report of the exact combination extents and the chloride content in the different natural substances.